The materials play the most important role in the outcome of our project when we are on woodworking and interior design. Hardboard (HDF), Medium Density Fiberboard (MDF), and Particle Board are three common wood-based materials frequently used in various applications. But what are they? What are their types, uses, and significances? How to choose them and when?

I will tell you about fiber and particle boards, the differences between HDF, MDF, and Particle Board materials, and their uses, advantages, disadvantages, types with sizes to help you select the right one for your next project.

What Are Fiberboard and Particle Board? What’s the Difference?

Fiberboards

Fiberboards are engineered wood products made from wood fibers. They are combined with resins and other binders and formed into panels under high temperature and pressure.

Hardboard, High-Density Fiberboard (HDF), Medium-Density Fiberboard (MDF), Pegboard, and Tempered Hardboard are well-known types or variations of fiberboard.

There is another type of hardboard, named HDHMR stands for high density high moisture resistance board. It is the highest kind of hardboard type, the upper kind of HDF.

Particle Boards

Particle board or chipboard is an engineered wood product made from wood particles such as wood chips, sawmill shavings, or even sawdust.

These wood particles are combined with a synthetic resin or suitable binder and then, pressed and extruded to form sheets or panels. Particle board is commonly used in various applications where cost is a primary consideration, and appearance and durability are less important.

Fiberboard VS Particle: What’s the Difference?

Fiberboard and Particle Board, both are engineered wood products, but they have notable differences.

Fiberboard:

- Made from wood fibers, resin, and wax.

- Smooth and uniform texture.

- Low “tear out” when cut.

- Excellent for painting and finishing.

- Mild resistance to moisture.

- Often used in furniture, shelving, decorative molding, and doors.

- Preferred for its heat and sound-insulating properties.

- Can be attached using various methods.

- As fiberboards are made from waste wood scraps, they are environmentally friendly.

Particle Board:

- Comprised of larger wood particles and synthetic resin.

- Less uniform and smooth texture.

- Prone to expansion and discoloration in high moisture.

- Less dense and weaker than fiberboard.

- They are used where cost is a primary concern.

- Sometimes utilized under the vinyl floor covering in bathrooms and kitchens.

- Lighter than fiberboard but less durable.

What Is Hardboard (HDF)?

Hardboard which is also known as high-density fiberboard (HDF), is a versatile engineered wood product. It is made by compressing wood fibers and resin under high pressure and heat, resulting in a dense and sturdy panel.

Types and Sizes of HDF

HDF, or High-Density Fiberboard comes in various types for specific applications. The sizes of HDF are 4×8 feet, 4×4 feet, and 2×4 feet, with thickness options ranging from 1/4 inch to 1/2 inch.

- Standard HDF: This is the most common type of HDF, known for its density and durability. It’s used in various applications such as furniture components, cabinet doors, and decorative panels.

- Tempered HDF: Tempered HDF is stronger and more impact-resistant than standard HDF. It’s suitable for applications that require extra durability, such as furniture components and decorative elements.

- Pegboard HDF: Pegboard HDF is perforated with regularly spaced holes. It is ideal for organizing tools, crafting supplies, and retail displays.

- Painted HDF: Some HDF comes pre-painted or primed to reduce the need for additional finishing work. They are suitable for applications where a smooth, painted surface is a priority.

Uses of Hardboard (HDF)

Hardboard is widely used for applications that require a smooth, hard surface.

- Furniture Backing: Hardboard provides stability and rigidity to the backs of cabinets, bookshelves, and other furniture.

- Cabinet Doors: Its smooth surface makes it an excellent choice for cabinet doors that require a painted finish.

- Floor Underlayment: As an underlayment, HDF serves as a flat, moisture-resistant base for flooring materials.

- Decorative Panels: HDF is also used for decorative wall panels, wainscoting, and room dividers.

Major Advantages of Hardboard (HDF)

- Smooth Surface: HDF offers a consistent, smooth surface that is ideal for painting or laminating.

- Stiffness and Durability: It is strong and resistant to bending. Thus it is suitable for structural applications like structural ply-board.

- Moisture Resistance: HDF is less susceptible to moisture damage compared to MDF and Particle Board.

- Highest Lifespan: HDF has the highest longevity than MDF and Particle board, but less than HDHMR. HDF-made products can last 15 to 18 years without laminating in a dry environment. It can last up to 24 to 27 years if you can laminate it properly.

Main Disadvantages of Hardboard (HDF)

- Load Bearing Issue: Though HDF is stiff, they are not as strong as MDF or plywood in some load-bearing applications.

- Not Ideal for Outdoor Use: It is not good for outdoor applications.

What Is Medium Density Fiberboard (MDF)?

MDF is another engineered wood product created by breaking down wood fibers and combining them with adhesives and heat. As they are dense, their uniform panels are ideal for various applications.

Types and Sizes of MDF

Medium Density Fiberboard, or MDF, is available in various types and sizes for different applications. The common size of MDF is 4×8 feet with various thickness options, ranging from 1/4 inch to 1 inch.

- Standard MDF: This is the most common type of MDF that is suitable for furniture, shelving, and molding.

- Moisture-Resistant MDF: Moisture-resistant MDF has additives that make it less susceptible to moisture damage. So, they are suitable for use in higher humidity levels areas such as bathrooms and kitchens.

Uses of MDF

- Cabinetry: MDF is commonly used for cabinet components like doors and shelves.

- Trim and Molding: It can be shaped into intricate moldings, baseboards, and other decorative elements.

- Furniture Making: MDF is used in furniture construction, especially for pieces that will be painted.

- Interior Doors: Interior doors made from MDF offer a smooth finish, so they are less prone to warping.

Major Advantages of MDF

- Fine Finish: MDF is prized for its smooth surface. It is an excellent choice for painting and veneering.

- Dimensional Stability: It maintains its shape and resists warping over time.

- Versatility: MDF can be cut, routed, and shaped into various forms for decorative and structural purposes.

- Moderate Longevity: MDF-made products last for 15 years without laminating. But if you put laminate properly like ply, then it can last up to 18 to 22 years.

Main Disadvantages of MDF

- Susceptibility to Moisture: MDF is not suitable for high-moisture environments, as it can swell or deteriorate. It is suitable for outdoor uses compared to HDF. In this case, you can consider OSB or Ply as per your need.

- Not Good for Heavy Loads: It may not be as strong as solid wood or plywood for applications requiring high load-bearing capacity.

What Is Particle Board?

You should already know that Particle board or chipboard is made by pressing together wood chips, sawdust, and adhesive under high pressure. It is an economical wood-based material widely used for budget-conscious projects.

Types and Sizes of Particle Board

Particle board is typically available in various thicknesses, such as 3/8 inch, 1/2 inch, 5/8 inch, and 3/4 inch, and in 4×8 feet sheets.

- Standard Particle Board: This is the most common type of particle board and is suitable for general-purpose applications.

- Moisture-Resistant Particle Board: This type of particle board is suitable for use in moisture-exposure areas like kitchens and bathrooms.

- Fire-Rated Particle Board: Fire-rated particle board is designed to resist combustion. So, it is ideal for areas where fire resistance is a concern such as commercial buildings.

Uses of Particle Board

- Economical Furniture: It is commonly used in the construction of budget-friendly furniture.

- Cabinet Interiors: Particle board is often used for the internal components of cabinets.

- Shelving: It serves well for basic shelving and storage solutions.

- Temporary Projects: It’s ideal for temporary or short-term projects for its affordability.

Major Advantages of Particle Board

- Cost-Effective: It is one of the most budget-friendly wood-based materials.

- Good Surface: Like MDF and HDF, particle board also offers a smooth surface suitable for finishing.

- Consistent Density: Its uniform composition ensures predictable performance.

Main Disadvantages of Particle Board

- Low Strength: Particle board is not as strong or durable as MDF or HDF.

- Susceptible to Moisture: It is highly vulnerable to moisture, thus it is totally unsuitable for wet areas.

- Limited Lifespan: Due to its lower durability, it has a shorter lifespan than other engineered wood-like materials such as HDHMR, HDF, MDF, OSB, and Ply. But well, it can last 5 years without laminating in a dry environment. If you laminate particle boards or seal them perfectly, they can last up to 12 to 15 years.

Traditional Wood vs. HDF or MDF: Which Is Better for Flooring?

Traditional hardwood or engineered wood flooring offers a wide range of species and finishes. They always offer you to achieve a specific look that complements your interior design.

Traditional hardwood and engineered wood flooring are available in various plank sizes, typically ranging from 2 to 8 inches in width and varying lengths. The thickness of the planks also varies, usually between 3/8 inch to 3/4 inch. The size and thickness depend on the type and style of flooring.

Traditional Wood vs HDF: Which Is Better for Flooring?

The choice between HDF and traditional hardwood or engineered wood flooring for your project depends on several factors.

- Budget: HDF is a cost-effective option for flooring underlayment. It is an excellent choice if you want to reduce project costs. But both real and engineered wood can be expensive. Well, if budget is not an issue, then solid wood flooring like Oak, Ash, Brazilian Cherry, Brazilian Walnut, and Maple wood flooring are the best.

- Traditional or Aesthetic Preferences: If you’re looking for a finished flooring surface that provides warmth, natural beauty, and a wide variety of styles and finishes, real wood flooring is the better choice for you.

- Moisture Resistance: If moisture resistance is a concern, HDF is a better choice for the underlayment. You can also use OSB for this kind of job.

HDF or MDF: Which Is Better for Flooring?

Medium Density Fiberboard (MDF) is generally not a good choice for flooring compared to HDF.

HDF underlayment panels are typically available in standard sizes like 4×8 feet, 4×4 feet, and 2×4 feet. These panels are typically 1/4 inch to 1/2 inch thick. The specific size and thickness you choose will depend on the requirements of your flooring project.

Why HDF (Hardboard) for Flooring?

- As HDF is known for its stiffness and durability, it is suitable for use as a subfloor or underlayment material.

- HDF provides a smooth and even surface, ensuring a level base for the flooring material to be installed on top.

- HDF is less susceptible to moisture damage compared to traditional Particle Board underlayments.

HDF or MDF or Particle Board: Which Is Good for Furniture?

Both medium-density fiberboard (MDF) and Hardboard (HDF) are popular choices except for particle or chipboard.

MDF is the preferred choice for furniture for its smooth finish, versatility, and dimensional stability. However, Hardboard (HDF) is a viable option for certain structural components.

- Standard MDF and moisture-resistant MDF (MR-MDF) with the latter are the most suitable options for furniture making.

- Between Standard and tempered hardboard, Tempered hardboard is stronger and more impact-resistant for furniture.

Which Is Better for Furniture?

MDF is an excellent choice for furniture pieces that demand a smooth, flawless finish, such as cabinet doors, shelving, and decorative elements. Its smooth surface is ideal for painting or veneering. And, its dimensional stability ensures the longevity of your furniture.

HDF is preferable for furniture components that require extra strength and rigidity, such as the backing of bookshelves or the structural elements of certain types of furniture. Its stiffness and durability make it suitable for these purposes.

- MDF is the more commonly chosen material for furniture projects due to its versatility, smooth surface, and ease of customization.

- But if your project demands extra strength and stiffness, then HDF is your savior.

Is HDF Better than MDF for the Kitchen?

If budget is your main concern, then MDF is more cost-effective than HDF.

The choice between HDF (High-Density Fiberboard) or MDF (Medium Density Fiberboard) for a kitchen highly depends on the specific application within the kitchen and your preferences. Let’s see.

HDF for Kitchen

- Cabinet Doors: HDF is a better choice for cabinet doors due to its flawless, and finished appearance. Its exceptionally smooth surface makes it ideal for painting or veneering.

- Backsplash Panels: If you’re considering a decorative or backsplash panel, HDF is a good option.

- Drawer Fronts: For drawer fronts that require a painted or laminated finish, HDF is an excellent choice.

MDF for Kitchen

- Cabinetry: MDF is a good choice for various cabinet components like cabinet boxes, shelves, and sometimes even cabinet doors.

- Drawer Boxes: MDF is often chosen for constructing drawer boxes for its stiffness and resistance to warping.

- Wainscoting and Moldings: MDF can also be used for wainscoting and various moldings, as it provides a clean and smooth finish.

Is HDF Good for Wardrobes?

HDF (High-Density Fiberboard) is a good choice for certain components of wardrobes and closet systems like wardrobe doors, shelving, back panels, and decorative elements.

Its smooth finish, strength, and durability make it a suitable option for wardrobe components, especially when you want a painted or laminated finish.

However, HDF is not ideal for high-moisture environments like many wood-based materials. If your wardrobe is located in a particularly humid area, you should protect the HDF by proper sealing or ventilation.

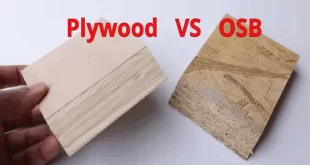

HDF vs. Ply: Is HDF Stronger than Plywood?

Generally, HDF (High-Density Fiberboard) is denser and harder than plywood.

- HDF is known for its high density and hardness. It is less prone to bending and warping compared to many other wood-based materials, including plywood.

- HDF’s superior dimensional stability and resistance to warping and sagging make it a good choice for applications that require a rigid and stable surface.

But you should know that plywood is not that weak you may think. The strength of plywood varies significantly depending on its type, grade, and the number of plies (layers).

Plywood is graded based on the quality of the face and back veneers and the overall construction.

- Marine-grade plywood is exceptionally strong and durable. Marine-grade plywood is a better choice than HDF where high strength and moisture-resistance both are priorities.

- While standard plywood may not be as dense as HDF, it is used for structural applications, such as in construction and furniture making.

MDF VS Plywood: Is MDF More Stable Than Plywood?

No! MDF is not more stable than plywood. To understand the matter clearly, see the below table.

| Parameter | MDF | PLYWOOD |

| Made Of |

MDF is made of wood fiber which is obtained from hardwood and softwood. The fibers are glued together with the help of wax and resin adhesive. Then, MDF is made under high temperature and pressure. |

Plywood is made from thin wood sheets. Thin wood sheets are glued together with the help of adhesive under high pressure and temperature to make plywood. |

| Strength | MDF is not as strong as plywood. It can be damaged at times. | Plywood is stronger than MDF. |

| Weight Carrying Ability | MDF can sag due to extra load. | As plywood is strong, it can carry more weight. |

| Workability | There is a risk of it splitting in two while screwing the MDF. | Plywood can easily be screwed into. It does not crack or split in two. |

| Cost | MDF is cheaper. | Plywood is expensive. |

From the compression table, you can understand that plywood is stronger and more durable than MDF. So, there is no doubt that Plywood is more stable than MDF.

But MDF is cheaper than plywood. If you don’t have enough budget, you should definitely use MDF.

When and Where to Use Particle Board?

Particle board or chipboard is very popular due to its affordability and versatility. It is significantly less expensive than other wood-based materials like plywood, MDF, or hardwood. Particle boards are used for temporary or short-term projects.

Standard Particle Board is the most common type of particle board and is suitable for general-purpose applications. Generally, it is available in various thicknesses, such as 3/8 inch, 1/2 inch, 5/8 inch, 3/4 inch, and 4×8 feet sheets.

- Shelving and Storage: A particle board is ideal for basic shelving and storage solutions, especially when a budget is a primary concern.

- Cabinet Interiors: In kitchen and bathroom cabinets, where the interiors are not on display, particle board can be used to create shelves and cabinet boxes.

- Furniture Interiors: While not typically used for visible surfaces in furniture, particle board is commonly employed for the internal components of furniture like dresser drawers, cabinet carcasses, and the structural elements of bookshelves.

- Backing or Substrates: A particle board is also used as a backing material for items such as wall-mounted cabinets, wall panels, and furniture backs. Its cost-effectiveness makes it a practical choice for these applications.

- DIY Projects: For DIY enthusiasts and hobbyists on a budget, particle board is an attractive option for various projects like workbenches, utility shelves, and craft tables.

- Fire-Resistance Project: Fire-rated particle board is designed to resist combustion. So, they are the ideal choice where fire resistance is a concern, such as in commercial buildings.

Note That:

- A particle board is not suitable for applications where moisture exposure is excessive, as it is highly vulnerable to swelling and deterioration when soaked.

- For those areas, materials like plywood or moisture-resistant MDF are better choices.

HDF vs. MDF vs. Particle Board: The Differences

The key differences between these wood-based materials are-

- Density: HDF is the densest and most rigid, followed by MDF, with Particle Board being the least dense.

- Smoothness: All three materials offer smooth surfaces, but HDF is known for its exceptional smoothness.

- Strength: HDF is the strongest, followed by MDF, while Particle Board is the weakest.

- Moisture Resistance: HDF is the most moisture-resistant, MDF is moderately resistant, and Particle Board is highly susceptible to moisture.

Let’s see the full comparison in a chart.

| Aspect | MDF

(Medium-Density Fiberboard) |

HDF

(High-Density Fiberboard) |

Particle Board |

| Density | Moderate density | High-density | Moderate density |

| Strength | Less strong than HDF | Stronger than MDF | Less strong than MDF and HDF |

| Smooth Surface | Smooth, ideal for finishing | Exceptionally smooth | Smooth, suitable for finishing |

| Moisture Resistance | Moderate moisture resistance | Better moisture resistance | Highly susceptible to moisture |

| Common Uses | Furniture, shelving, molding | Flooring underlayment, structural applications, furniture backing | Budget furniture, shelving, temporary solutions |

| Types and Sizes | Standard and moisture-resistant MDF in various thicknesses and sizes | Standard and tempered HDF in various thicknesses and sizes | Standard and moisture-resistant Particle Board in various thicknesses and sizes |

| Budget Considerations | Moderately priced | Slightly more expensive than MDF | Economical, budget-friendly |

Can HDF, MDF, and Particle Board Be Painted?

Yes, HDF (High-Density Fiberboard), MDF (Medium Density Fiberboard), and Particle Board can be painted like real wood.

Painting makes these engineered woods smooth, consistent surface, and versatile. Thus painting them is a common choice for projects that require a refined and finished appearance like cabinet doors, furniture components, shelving, and decorative panels.

Generalized Steps: How to Paint MDF, HDF, and Particle Board?

Surface Preparation:

Proper surface preparation is essential for achieving a high-quality paint finish.

- First, sand the surface to smooth out any imperfections, rough spots, or edges.

- Use fine-grit sandpaper to create a uniformly smooth surface.

- After sanding, clean the surface to remove any dust or debris.

Priming:

To improve paint adhesion and prevent these boards from absorbing too much paint, it’s you must apply a suitable primer before painting.

Paint Selection:

Various types of paint can be used on MDF, HDF, and Particle boards, but latex or oil-based paints are the most suitable. The choice of paint should depend on your preferences and the type of finish you want to achieve.

Painting Techniques:

- Apply the paint using even strokes when painting them.

- You may need multiple coats of paint to achieve the desired finish.

- Paint the boards in the direction of the wood grain (if visible) because then you’ll get a more natural look.

Sealing:

After the paint has dried, you should apply a clear topcoat or sealant to protect the painted surface and enhance its durability. You can also use the Powder coat or Polyurethane for extra protection if the criteria match to use this kind of coating or sealing.

Drying Time:

Finally, allow each coat of paint and the primer (if used) to dry thoroughly before applying subsequent coats. You should follow the manufacturer’s recommendations for drying times if you are not experienced enough.

How to Select the Right Material for Your Project?

First, you must identify your project needs. You must determine the primary purpose of the engineered wood in your project. Are you looking for a smooth, paintable surface, or is structural strength more important? After clearing these questions, you can easily choose the right material for your projects.

No worries, my friend! Now I’m giving you a checklist.

1. Consider the Application

- MDF or HDF is a good choice for furniture components, shelving, and decorative elements where a smooth surface is required.

- If you need material for structural applications, such as flooring underlayment, furniture backing, or areas that require stiffness and durability, HDF is preferable.

2. Durability Requirements

HDF is denser and stiffer than MDF. You should choose HDF for projects that need added strength and resistance to bending or warping, such as furniture structural components.

3. Evaluate Moisture Exposure

- If your project is in an area with moisture exposure, like kitchens or bathrooms, consider HDF or MDF.

- Both have better moisture resistance compared to the Particle Board.

4. Customization

If your project needs intricate detailing or custom design elements, both MDF and HDF are suitable for you. Because they can be easily customized through cutting, routing, and shaping.

5. Finish and Paint

If your project requires painting or finishing, all three engineered wood options can be painted. But MDF and HDF provide exceptionally smooth surfaces for a polished look.

6. Surface Finish

- If you require an exceptionally smooth surface for painting or veneering, both MDF and HDF are suitable.

- MDF is known for its smooth finish, while HDF offers an even smoother surface.

7. Budget Issue

If cost is your primary concern, then Particle Board is your most budget-friendly option.

Moreover, MDF is a more affordable material than HDF for projects that require a smooth, paintable surface and moderate durability.

Particle Board vs MDF vs HDF: What’s the Main Catch Here?

Hardboard (HDF), MDF, and Particle Board each have their strengths and weaknesses. But there is no doubt that they are reasonable and suitable for different purposes.

- If you need a strong and moisture-resistant material with a very smooth surface, HDF is the top choice.

- For versatility, durability, and a smooth finish, MDF is an excellent option for various indoor applications.

- When cost is a primary concern, and moisture resistance is not required, Particle Board offers an economical solution for basic projects.

If you are here, then you should have the ability to make a great decision for yourself now. Have a good day, folks!

WoodReminder Let's Explore Wood's Universe

WoodReminder Let's Explore Wood's Universe